Imagine a machine not-unrelated to the inkjet printer on your desk being able to create living organs, tissue and joints for transplant. It’s called bioprinting, and while it’s not going to happen tomorrow, research at major labs across the country indicates it is definitely the future. One of those labs is run by Dr. Ibrahim Ozbolat at the University of Iowa, who teaches in the Department of Mechanical and Industrial Engineering and does research with the Center for Computer-Aided Design's Biomanufacturing Laboratory. In an article published in the January 2012 issue of Mechanical Engineering Magazine (MEM) entitled “Printed Life,” Dr. Ozbolat’s research on microfluidic vessel-like containers to house the printed cells and the fascinating world of 3-D bioprinting are explored in depth. [Photo of Dr. Ozbolat courtesy of University of Iowa]

Imagine a machine not-unrelated to the inkjet printer on your desk being able to create living organs, tissue and joints for transplant. It’s called bioprinting, and while it’s not going to happen tomorrow, research at major labs across the country indicates it is definitely the future. One of those labs is run by Dr. Ibrahim Ozbolat at the University of Iowa, who teaches in the Department of Mechanical and Industrial Engineering and does research with the Center for Computer-Aided Design's Biomanufacturing Laboratory. In an article published in the January 2012 issue of Mechanical Engineering Magazine (MEM) entitled “Printed Life,” Dr. Ozbolat’s research on microfluidic vessel-like containers to house the printed cells and the fascinating world of 3-D bioprinting are explored in depth. [Photo of Dr. Ozbolat courtesy of University of Iowa]

Most people are familiar with computer-aided design (CAD) technology from architectural renderings, or the 3-D holographs of facial and bodily reconstructions of hi-tech forensic TV dramas. In the biomedical world, 3-D CT and MRI scans are digitized using CAD systems. CAD technology is also used in manufacturing, to create product model simulations as well as actual objects using digital device manufacturing (DDM).

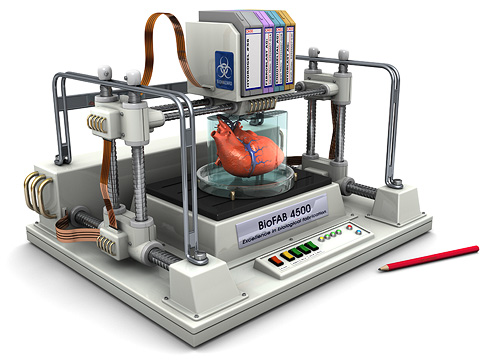

[Conceptual bioprinter, courtesy of Christopher Barnatt]

Your inkjet printer works by distributing droplets of ink in a 2-dimensional layered pattern created by going back and forth horizontally as well as vertically (in rows). A 3-D printer could actually ink out a solid object made up of many thin layers of inkdrops. The ink comes from cartridges mounted above the printer head. Now replace the ink with human cells and some sort of fluid to give them structural support initially and you have a bioprinter like the one imagined above, which holds cartridges labelled: Hydrogel, Fibroblast, Endothelial, and Myoblast. The cells will be your own, augmented with some sort of stem cell technology to promote growth, and the resulting organ will have been designed to the exact specifications of your body’s existing or ideal organ.

Dr. Ozbolat’s bioprinting research focuses on engineering the microfluidic vessel-like chambers that will one day stand in for the capillaries and vessels that pump blood through complex printed organs to supply nutrients and oxygen during the build up of printed cells, according to the MEM article. His team is working on a coaxial printer nozzle design that will eventually print a filament with a hollow core to mimic blood vessels. Currently human cells are cultured on an artificial scaffold that may or may not disintegrate as the (stem) cells generate a new organ (see our blog on a successful trachea transplant using this technology).

The University of Iowa in Iowa City runs the largest academic medical enterprise in the state, as well as one of the preeminent life science research institutions in the Midwest. Expect the line between medicine and manufacturing (or living organisms and mechanical objects) to continue to blur over the next decade, in a phenomenon that English science writer and professor Christopher Barnatt refers to as The New Industrial Convergence. As we move forward in that convergence of biologic and mechanical, we’ll see more engineers working in collaboration with medical researchers to design and heal the human body, like Dr. Ozbolat and his bioprinting colleagues.

[The Carver College of Medicine, courtesy of the University of Iowa]

Biotechnology Calendar, Inc. invites all life science researchers (biomedical as well as bioengineering) to step out of their labs on May 3, 2012 and attend the 10th Annual Iowa BioResearch Product Faire ™ FrontLine event on the University of Iowa health sciences campus. This BRPF event is an excellent opportunity for scientists, purchasing agents, and lab managers to meet and network with laboratory equipment suppliers and explore the latest lab science technologies to further their research. If you are a vendor interested in exhibiting, click below: