As life science researchers find more and more applications for laboratory-grown cells, methods for cultivating a large amount of cells quickly are becoming more and more valuable. Looking beyond the basic criteria like temperature and sustenance, bioengineers at Ohio State University are finding that the surface cells are grown on makes a dramatic difference in their rate of growth.

It’s customary to think of cells being grown on some flat surface, like perhaps a glass dish or plastic sheet. But professors Sheikh Akbar and Derek Hansford (left and right, respectively, courtesy of OSU) wondered if changing this classic breeding ground would have any effect on the cells. In fact, it turned out that cells proliferate much more on what the researchers call a microbial shag carpet.

It’s customary to think of cells being grown on some flat surface, like perhaps a glass dish or plastic sheet. But professors Sheikh Akbar and Derek Hansford (left and right, respectively, courtesy of OSU) wondered if changing this classic breeding ground would have any effect on the cells. In fact, it turned out that cells proliferate much more on what the researchers call a microbial shag carpet.

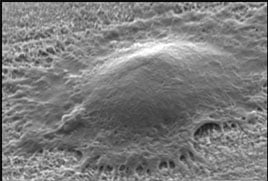

This “carpet” is created by heating a sheet of titanium to 1300 degrees Fahrenheit in a special blend of gases. The gases and heat cause tiny strands of titanium dioxide, each thousands times smaller than a human hair, to protrude from the surface of the sheet. The result is that growing cells are exposed to both titanium and titanium oxide at the same time, which makes them spread faster for some reason. As Akbar says in an OSU article, “It’s strange that we don’t completely understand why this process works the way it does. We’re going to have to do some fancy microscopy to figure it out,” but the team’s first priority is finding what works and then explaining why it does.

Not entirely convinced that the texture of the surface was responsible for the increased rate of growth, Akbar and Hansford tried growing cells on smooth sheets of titanium and titanium oxide, respectively. Both sheets ended up hosting 50,000 cells per square centimeter on their surfaces. The same test applied to the carpet structure yielded 90,000 cells per square centimeter- an 80% increase over the other two platforms.

(A cell attaches to the filaments of the titanium "carpet". Courtesy of osu.edu)

The most impressive part of this study beyond this stunning increase in cell growth is the ease with which it can occur. After gathering the proper chemicals, all that’s required is turning on a furnace. “Seriously, if you spent the day in my lab, you could learn how to do it yourself,” says Akbar. The mothd is also very cheap: the team can make hundreds of these samples with only $100 worth of metal foil.

Hansford sees potential for this technology to take off in helping patients to heal faster, especially in cases where patients already require titanium in their body. These metal parts, such as screws and plates, can be doctored using this method to help nearby cells repair and grow around them at a much quicker rate. Hansford elaborates: “Our hope is that this surface treatment will become a simple-to-implement modification to titanium implants to help them form a stronger interface with surrounding bone tissue…and we can better preserve healthy bone and soft tissue around the implant site.”

This study was partially funded by by grants from the NSF. For more detail on the funding for research at Ohio State University, peruse our Ohio State University Funding Report:

Biotechnology Calendar, Inc. is on the Ohio State University Campus today, August 8th, 2013 for our Columbus BioResearch Product Faire™ event. This show is an excellent opportunity for life science scientists and laboratory equipment suppliers to network and discuss their research needs and solutions. To see our 2013 show schedule, click here.